Features

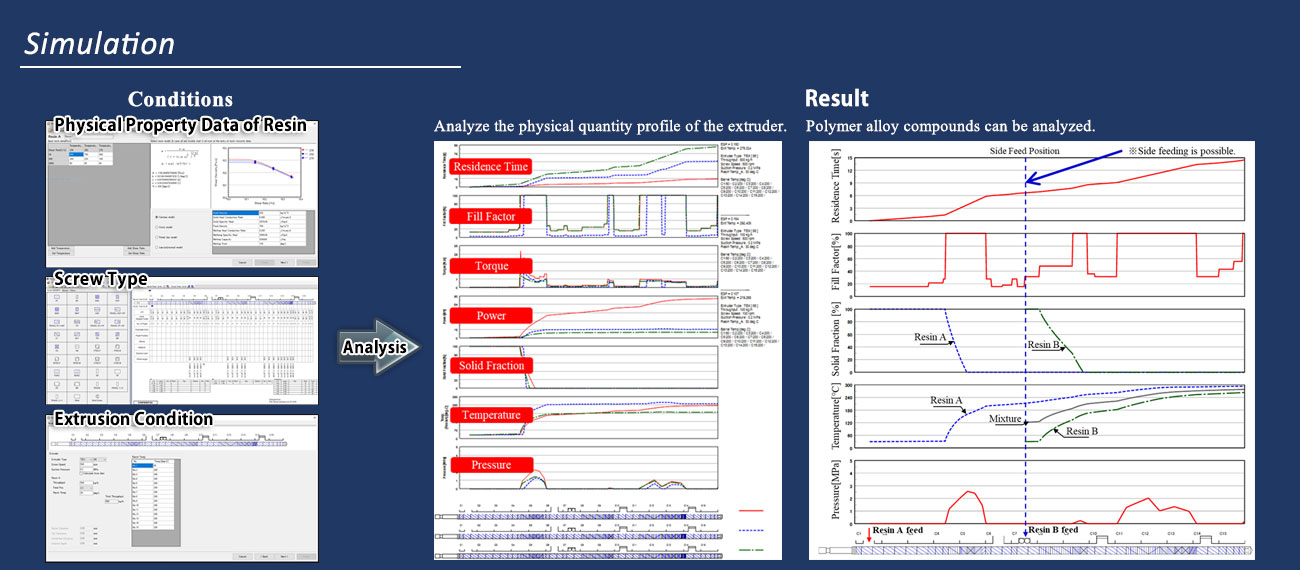

- The extrusion process can be evaluated.

- A virtual extrusion test can be performed on a PC to determine the optimum screw and operating conditions for the application.

- It takes about five minutes from setting the analysis conditions to completing the analysis.

Analysis function

- By specifying properties of feed materials and condition of extruding operation, such factors are analyzable as fill factor, pressure, temperature, plasticizing degree, residence time, dispersion and distribution of resin, motor power, torque and specific energy.

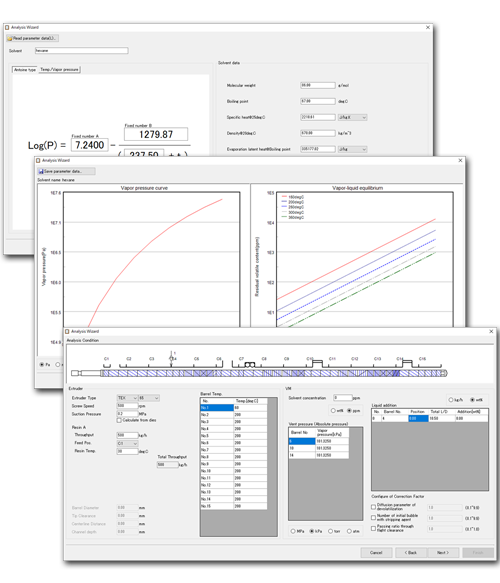

- This allows the user to predict a devolatilization process in which melt polymer containing much solvent (volatile material) is supplied to a twin screw extruder and the volatile material is devolatilized in the vent zone of the extruder.

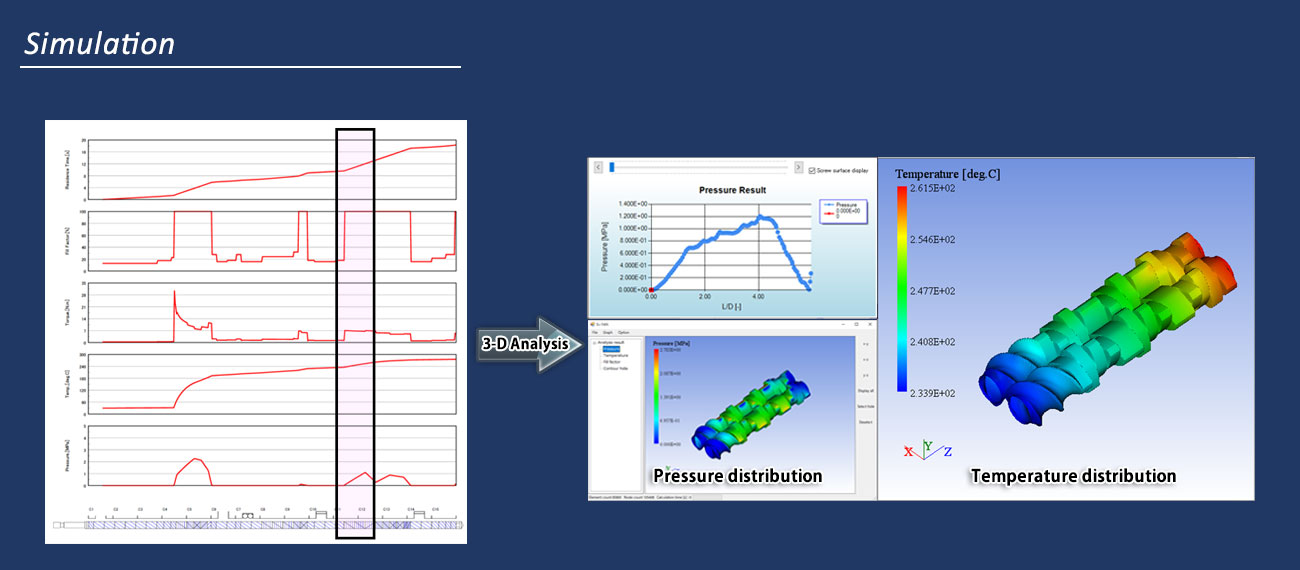

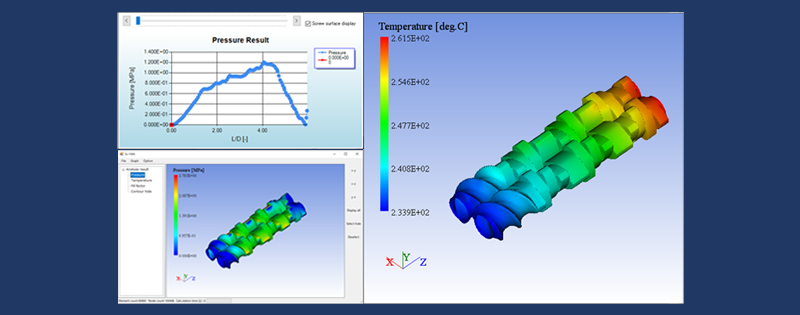

※This analysis software is an optional version. - Enables to run analyze localized area by 3-D analysis.

Advantage

- Simulation can shorten the testing period and speed up the process to production.

- Prediction and study of extruder scale-up can be simulated.

Details of each version

| Normal version | Devolatilization version(optional version) | TEX25 version | |

|---|---|---|---|

| Normal analysis | ○ | ○ | △ ※Only TEX25 can be analyzed. |

| Analysis of devolatilization process | × | ○ | × |

| User-Subroutine functions (provides user-defined process prediction function by user-subroutines in addition to the existing TEX-FAN functions.) |

× | ○ | × |

| 3-D analysis | ○ | ○ | × |

| Analysis of polymer alloy compounding | ○ | ○ ※Cannot be used in conjunction with prediction of devolatilization process. |

○ |

Hardware requirements

| Ver3 | |

|---|---|

| CPU | 2GHz or higher |

| Memory | 3Gbytes or larger |

| Hard disk | 600Mbytes or larger free space (.NET Framework space included) |

| Display | Display monitor of WXGA+(1440×900) or higher resolution |

| Disk drive | CD-ROM drive |

| Operating System | Windows8.1(32/64bit) Windows10(32/64bit) |

| Additional software | Adobe Reader |

Details of each version

| Normal version | ||

|---|---|---|

| Normal analysis | ||

| ○ | ||

| Analysis of devolatilization process | ||

| × | ||

| User-Subroutine functions (provides user-defined process prediction function by user-subroutines in addition to the existing TEX-FAN functions.) | ||

| × | ||

| 3-D analysis | ||

| ○ | ||

| Analysis of polymer alloy compounding | ||

| ○ |

| Devolatilization version(optional version) | ||

|---|---|---|

| Normal analysis | ||

| ○ | ||

| Analysis of devolatilization process | ||

| ○ | ||

| User-Subroutine functions (provides user-defined process prediction function by user-subroutines in addition to the existing TEX-FAN functions.) | ||

| ○ | ||

| 3-D analysis | ||

| ○ | ||

| Analysis of polymer alloy compounding | ||

| ○※1 |

| TEX25 version | ||

|---|---|---|

| Normal analysis | ||

| △※2 | ||

| Analysis of devolatilization process | ||

| × | ||

| User-Subroutine functions (provides user-defined process prediction function by user-subroutines in addition to the existing TEX-FAN functions.) | ||

| × | ||

| 3-D analysis | ||

| × | ||

| Analysis of polymer alloy compounding | ||

| ○ |

※1 Cannot be used in conjunction with prediction of devolatilization process.

※2 Only TEX25 can be analyzed.

動作環境

| Ver3 | ||

|---|---|---|

| CPU | ||

| 2GHz or higher | ||

| Memory | ||

| 3Gbytes or larger | ||

| Hard disk | ||

| 600Mbytes or larger free space (.NET Framework space included) | ||

| Display | ||

| Display monitor of WXGA+(1440×900) or higher resolution | ||

| Disk drive | ||

| CD-ROM drive | ||

| Operating System | ||

| Windows8.1(32/64bit) Windows10(32/64bit) |

||

| Additional software | ||

| Adobe Reader |

more information

Contact Us

Contact Us

Already purchased

Login

Login